BELT CONVEYOR

Belt conveyors have become one of the most important equipment in the entire production process.

BELT CONVEYOR

The structure is advanced, the adaptability is strong, the resistance is small, the service life is long, the maintenance is convenient, and the protection device is complete, which is a remarkable feature of the belt conveyor. It is one of the important equipments in the entire production process.

- Low resistance

- long lasting

- Easy to maintain

- High security

WIDE RANGE OF APPLICATIONS

Before the belt conveyor is running, first confirm that the belt conveyor equipment, personnel, and articles being transported are in a safe and intact state; check whether the electrical circuit is normal, and the belt conveyor can be put into operation normally.

- Low resistance

- long lasting

- Easy to maintain

- High security

PRODUCT ADVANTAGES

Use advanced manufacturing techniques to liberate front-line workers and replace advanced labor-intensive production methods with advanced production methods.

WIDE RANGE OF USES

The belt conveyor is also called belt conveyor. The conveyor belt moves according to the principle of friction transmission. It is suitable for conveying powdery, granular and small pieces of low-friction materials and bagged materials, such as coal and gravel. , sand, cement, fertilizer, food, etc.

Efficient/Convenient

Efficient/Convenient

-

OPERATING TEMPERATURE

OPERATING TEMPERATURE

The belt conveyor can be used in the ambient temperature range of -20 ° C to +40 ° C, and the material temperature to be sent is less than 60 ° C.

-

CUSTOMIZABLE LENGTH

CUSTOMIZABLE LENGTH

The captain and assembly form can be determined according to the user's requirements. The drive can be used with an electric roller or a drive device with a drive frame.

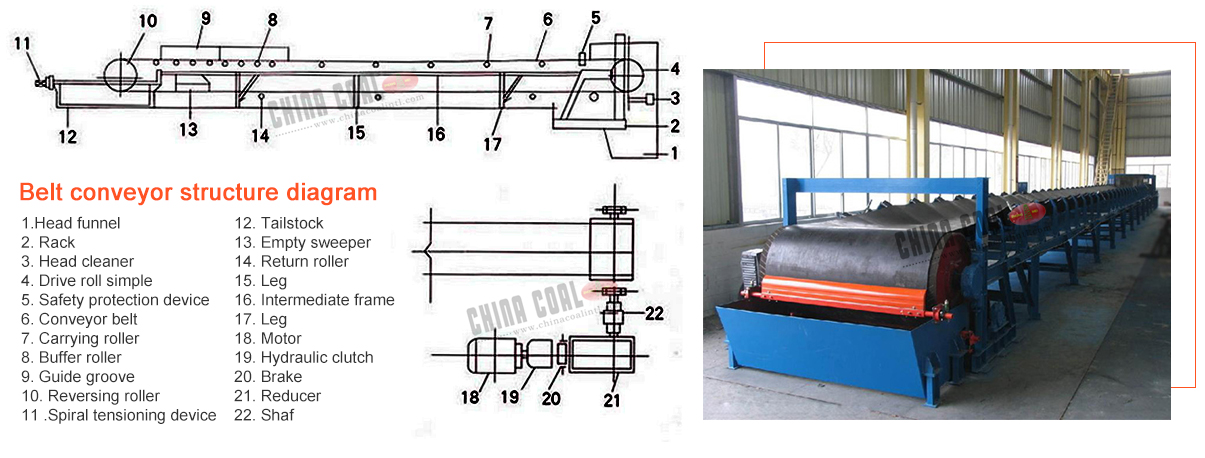

SHOW DETAILS

The belt conveyor consists mainly of two end rollers and a closed conveyor belt tightly fitted over it. The drum that drives the belt to rotate is called the drive drum (drive drum); the other drum that only changes the direction of movement of the belt is called the redirecting drum.

Automation and centralized control

Automation and centralized control

The belt conveyor is an ideal high-efficiency continuous transportation equipment for coal mines. Compared with other transportation equipment (such as locomotives), it has the advantages of long conveying distance, large volume and continuous transportation, and it is reliable in operation and easy to realize automation and centralized control. Especially for high-yield and high-efficiency mines, belt conveyors have become the key equipment for mechatronics technology and equipment for coal mining.

-

The belt conveyor body is retractable and easy to assemble and disassemble.

-

Can be equipped with intermediate drive

-

The multi-machine combined transport system transports materials.

HIGH-STRENGTH CONVEYOR BELT

Conveyor belt connection: Generally, vulcanization connection should be adopted. The static strength retention rate of the conveyor belt at its vulcanized joint should be no less than 100%, and the service life is generally not less than 10 years.

The permanent and elastic elongation is not more than 0.2%. The technical conditions must meet the requirements of the MT668 standard.

Manufacturers integrated direct sales products, rest assured to buy.

ANTI-RUNNING ROLLER

The belt conveyor is a grooved centering roller set. The grooved centering roller set is 35°. The belt conveyor backhaul roller uses the self-aligning roller set to prevent the conveyor belt from running off, centering and adjusting the deflection.

The roller shall not enter the bearing grease after continuous operation for 200 hours in a container with coal dust. Under continuous water conditions, the water intake should not exceed 150g after continuous operation for 72 hours.

BELT CONVEYOR PARAMETER REFERENCE

BELT CONVEYOR PARAMETER REFERENCE

DT75 belt conveyor technical parameters

| Bandwidth (mm) |

500 |

650 |

800 |

1000 |

1200 |

1400 |

| Belt speed (m/s) |

0.8-2.5 |

0.8-2.5 |

1.0-3.15 |

1.0-3.15 |

1.0-4.0 |

1.0-4.0 |

| Conveying capacity (t/h) |

78-232 |

131-391 |

278-824 |

435-1233 |

655-2202 |

891-2996 |

| Power (kw) |

1.5-30 |

1.5-40 |

1.5-7.5 |

3-100 |

4-185 |

4-185 |

<