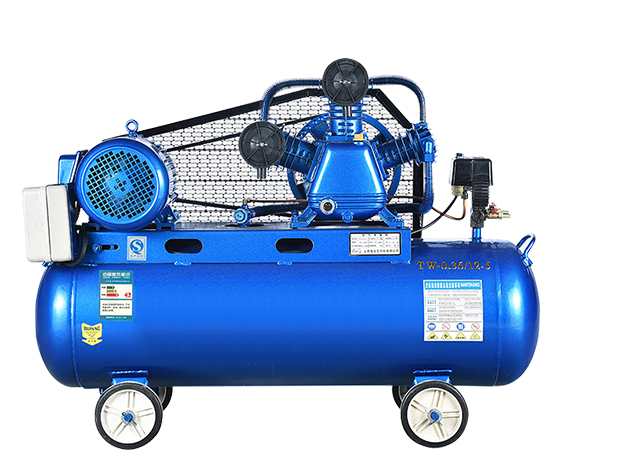

V-0.17-8 Belt Driven

Air Compressor

High sensitivity, strong anti-interference, overload protection, control pressure cycling.

Buy Now

Air Compressor

Powerful Operation Product Application

Air compressors are widely used for pneumatic reinforcement. Pneumatic tools, tire inflation, blowing processes, painting, sand blasting, jet components and other air-conditioned airports.

Easy To Navigate

In a Variety Of Situations

Air Compressor

Powerful Operation Product Characteristics

china coal

china coal

Air Compressor

Strength Business

International Motor

International Motor Run Smoothly

Run Smoothly Safety Tank

Safety Tank  Powerful

Powerful Operational Safety

Operational Safety Energy Saving

Energy Saving

01

china coal

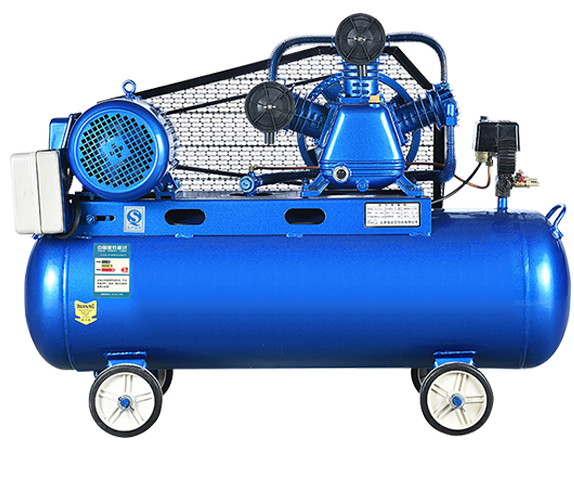

Precision grade good quality

The imported precision die casting machine is die-casted once to ensure that each part achieves design accuracy.

02

china coal

Industrial boutique Durable

With new high-quality materials, wear-resistant, and constantly research and development of new products, just to bring you a more comfortable experience.

Thickened shockproof casters Thickened shockproof casters Made of high quality material PC material, anti-shock, low noise mute, thick and durable.

Double outlet Safe to use, safe and fast, stable operation and good sealing effect.

03

china coal

Strong power stable operation

High-quality copper motor gives you strong power, driving high speed and running more stable.

Air Compressor

Powerful Operation Product Advantage

-

01

Run Smoothly

The vibration is small, the sound is small, and the operation is stable.

-

02

Industrial Boutique Durable

Mechatronics products reduce maintenance costs.

-

03

Copper Electromechanical

The pure copper wire movement has fast heat dissipation and strong power, which is twice the gas output of the traditional air compressor.

Air Compressor

Powerful Operation Product Composition

Air Compressor

Powerful Operation Product Precautions

It is a device for compressing gas, which is a device that converts the mechanical energy of a motive (usually an electric motor) into gas pressure energy. Air compressors are similar in construction to pumps, and most air compressors are reciprocating pistons, rotating blades or rotating screws. Centrifugal compressors are very large applications.

Precautions Of Air Compressor

-

Air compressor precautions:

1. When the air compressor is shut down due to power failure, in order to prevent the compressor from starting with pressure, the pressure switch should be pulled off when the power is turned on, the air in the pipeline is drained, and the compressor is restarted.

2. When the air compressor finds serious air leak, abnormal noise, and odor, stop running immediately, and find out that the cause can be re-run after the fault is restored.

-

Air compressor precautions:

3. The air compressor must be fixed to a ventilated, stable and sturdy work surface. To reduce noise and vibration, a shock absorber must be provided.

4. The compressor is maintained at least once a quarter. The maintenance includes thoroughly removing the dust and dirt from the compressor, checking and tightening the connecting bolts around the compressor, whether the grounding wire is intact, and checking the electrical circuit for aging damage.