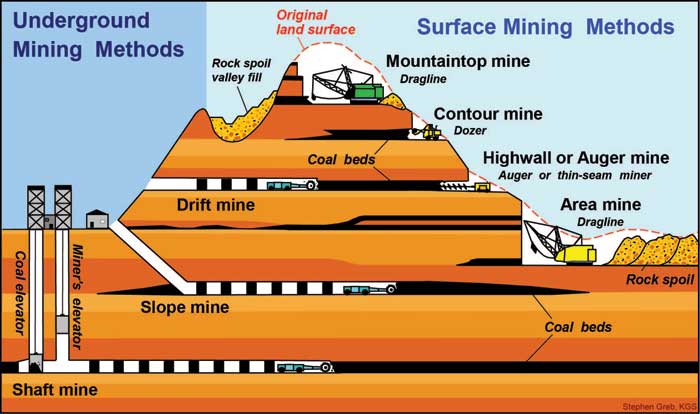

Underground coal mining mainly include the process of drift, slope, and shaft mining, and actual mining methods include longwall and room and pillar mining.

Drift Mines enter the side of a hill horizontally and mine the coal within the hill. Slope mines usually begin in a valley bottom, and a tunnel slopes down to the coal surface. Shaft mines are the deepest mines; a vertical shaft with an elevator is made from the surface down to the coal. In western Kentucky, one shaft mine reaches 1,200 feet below the surface.

The most common type of underground coal mining are room mining and pillar mining, coal seams are mined by a "continuous miner" that cuts a network of "rooms" into the seam. As the rooms are cut, the continuous miner simultaneously loads the coal onto a shuttle or ram car where it will eventually be placed on a conveyor belt that will move it to the surface. "Pillars" composed of coal are left behind to support the roof of the mine. Each "room" alternates with a "pillar" of greater width for support. Using this mining method normally results in a reduction in recovery of as much as 60 percent because of coal being left in the ground as pillars. As mining continues, roof bolts are placed in the ceiling to avoid ceiling collapse. Under special circumstances, pillars may sometimes be removed or "pulled" toward the end of mining in a process called "retreat mining." Removing support during retreat mining can lead to roof falls, so the pillars are removed in the opposite direction from which the mine advanced: hence the term "retreat mining."

Longwall mining is another type of underground mining. Mechanized shearers are used to cut and remove the coal at the face of the mine. After the coal is removed, it drops onto a chain conveyor, which moves it to a second conveyor that will ultimately take the coal to the surface. Temporary hydraulic-powered roof supports hold up the roof as the extraction process proceeds. This method of mining has proven to be more efficient than room and pillar mining, with a recovery rate of nearly 75 percent, but the equipment is more expensive than conventional room and pillar equipment, and cannot be used in all geological circumstances. As mining continues, roof bolts are placed in the ceiling to avoid ceiling collapse. In longwall mining, only the main tunnels are bolted. Most of the longwall panel is allowed to collapse behind the shields (which hold the roof as coal is excavated).