MLC Material Supply Mine Wagon

Application, Feature

Pictures for reference only. More details please contact sales for confirm.

MLC Material Supply Mine Wagon

Mine car is an narrow gauge railway transport vehicle used in coal mines which conveying bulk material such as coal mine, ore and ballast stone.

MLC Material Supply Mine Wagon

This series MLC Material Supply Mine Wagon used for underground and roadway narrow garuge railway transport.

MLC Material Supply Mine Wagon

Metal structure frame which can withstand the traction, self motivation, car collision between impact force and the rail.Simple structure, durable, small resistance coefficient,large capacity, easy maintenance.,reduces the impact of stress and increases the service life by adopting the car frame in welding structure,ensure operating smoothly no matter on curve or straight rail.

Defination

M

Mining UseL

MLC Material Supply Mine WagonC

mine carM

Loading tM

GauageM

Design Version(A,B)

eg:MLC3-9A Mine Car

version A, 3T loading, 900mm guage material supplying mine car

Parameters

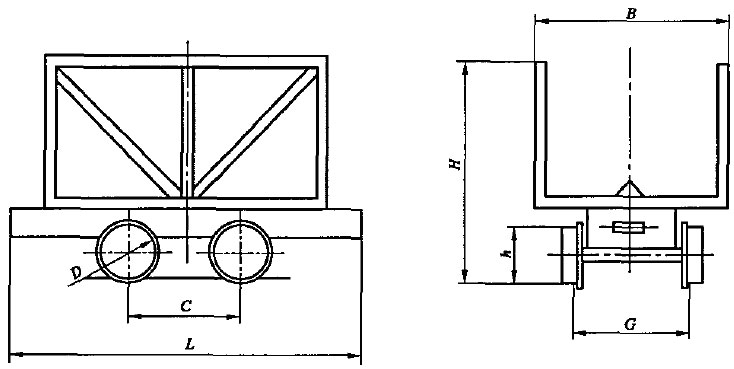

Pictures for reference only. More details please contact sales for confirm.

| Model |

Loading

/t |

Gauge G |

Dia |

Wheelbase

C |

Wheel Dia

D |

Traction

Height

h |

Max

Traction

/kN |

Mix

Flat Radius

m |

Weight

/Kg |

| Length L |

Width B |

Height H |

| mm |

| MLC2-6 |

2 |

600 |

2000 |

880 |

1150 |

550 |

300 |

320 |

60 |

9 |

≤520 |

| MLC3-6 |

3 |

600 |

2400 |

1050 |

1200 |

750 |

300 |

320 |

60 |

9 |

≤570 |

| MLC5-6 |

5 |

600 |

3450 |

1200 |

1200 |

1100 |

350 |

320 |

60 |

12 |

≤920 |

| MLC5-9 |

5 |

900 |

3450 |

1320 |

1300 |

1100 |

350 |

320 |

60 |

12 |

≤940 |

| MLC3-9A |

5 |

900 |

2100 |

1150 |

1300 |

600 |

350 |

320 |

60 |

12 |

≤790 |

| Note: Height H and Traction Height h measure from the rail surface. |

MLC Material Supply Mine Wagon

transports material for underground coal mine and roadway by the traction of locomotive or winch.

Main Structure

Pictures for reference only.Please contact sales for confirm.

MLC Material Supply Mine Wagon

mainly consists of frame, buffer, wheel set (open wheel set, closed wheel set),connection device, etc.

The frame is designed into metal structure, which can withstand the traction,the car collision between impact force and the rail, welded by channel steel, meet, shaft card.Its technical conditions comply with the provisions of the "JB/T6992-1993".

The frame fashioned iron should be straightened not be larger than 1.5 ‰ before plug weld. Two frame sides parallel degree of tolerance for the length of 2 ‰.The flatness tolerance of the flame is 2 ‰ to the frame length (buffer not included ), but the max flatness tolerance should less than 5 mm.

The center of the frame surface traction device should be symmetry to the longitudinal center plane of the frame, and its symmetry tolerance should not exceed 6mm.

Closed Wheel Set

Grease, dirt, the scrap iron and blockage should be removed before attempting assembling.

Wheel should not appear crack, 10 mm in length range appeared on top of the rim and the end part of the profile of tiny crack, should not be more than two.

Tread should not be welded,except within the following limits allowed.

Surface defects such as trachoma, porosity of round hole,that the area smaller than 16 mm2, the depth is less than 3 mm, 30 mm apart or more, shall not exceed three.

To die casting wheel,the round beating quantity of the wheel diameter D should not be larger than 1 mm;To sand casting wheel, the circular runout amount should not be larger than 0.5 mm.

The wheel after normalizing organization should not shown network structure, its grain size should not be larger than 6.

Axle bearing installed on both ends of the coaxial degree.Should comply with the provisions of the figure below.

| Unite mm |

| Diameter |

50 |

55~80 |

| Coaxiality |

0.04 |

0.06 |

Open Wheel Set

Constituted by wheel,shaft,bearing,etc.Its technical conditions comply with the provisions of "JB/T6992-1993".

Clean the iron and blockages, and clean the parts before front wheel assembly,bearing should assembled by no shock load method, make sure the wheel rotation flexibility.

Assembling Requirements

Before assembling,all the parts should be inspection qualified.

All parts should be clean, and assembly in a clean environment.

Assembled dimension deviation: the total width of mine material car and the high traction deviation of ± 3 mm, total high deviation of ± 8 mm, length deviation of ± 10 mm.

Deviation of the length of the MLC Material Supply Mine Wagon of - 10 ~ 0 mm, width deviation of plus or minus 3 mm.

Assembled mine material car should be placed in a special flat road inspection,and a larger than 2mm gap on the surface of the wheel and rail is not allowed.

Bumper

Bumper technical conditions in accordance with the provisions of the JB/T6992-1993

Buffer has enough strength, cushioning material toughness value of not less than 30J/cm2

cast steel bumpers there shall be no crack, on the surface of cast steel bumper bolt hole and end face (from the bolt hole edge 30mm range) not allowed on shrinkage and porosity and impact strength of the blowhole, sand inclusion defect and shall not carry out welding.

The connection device is composed of connection three-ring chain, connecting bolt.

Connection three-ring chain conforms with the standard requirements of" MT 244.1 - 2005 coal mine narrow gauge vehicle fittings connection chain ".

Connecting pin conforms with the standard requirements of"MT 244.2-2005 mine narrow gauge vehicle connector connecting pin".

Welds should be even and level, there should be no cracks, inclusions, burn, incomplete penetration defects,

| Unit mm |

Steel Sheet Thickness

|

≤10 |

>10~40 |

| Depth of Undercut |

0.5 |

1.0 |

Installation

Pictures for reference only.Please contact sales for confirm.

Preparation before installation

Check the installation location of the mine material car, check the track laying conditions,check if two parallel rails, flatness meets the requirements, and adjust if necessary.The top of a rail line should be at the same level, length direction of the allowable error for each meter of no more than 1mm, each 10m of no more than 3mm. Measuring points on the left and right direction corresponds to the allowable error is less than 2mm.

Installation

According to the requirements of installation, ensure that the centerline of the car wheel and centerline of the orbit being superposed.

Commissioning

Observe whether the mine material car wheels rub on the track,handle it in time to prevent damage to the mine material car once the phenomenon occurs. Observe whether the mine material car tilt,out of orbit or overturned after it sliding along the slope curve and colliding with another car.

Attentive Proceedings

Mine material car should be carefully examined whether the appearance of serious damage to bump phenomenon, the wheels should be flexible rotation, no obstruction before use.

Mine material car normal service 10000hs above,generally need no maintenance. However, according to the use of premises and load size, appropriate maintenance oiling maintenance date should be developed, timely cleaning oiling maintenance.The wheel that has abnormal noise and does not turn should be promptly replaced.

Warning

Mine material car should be operatee strictly in accordance with the procedures.