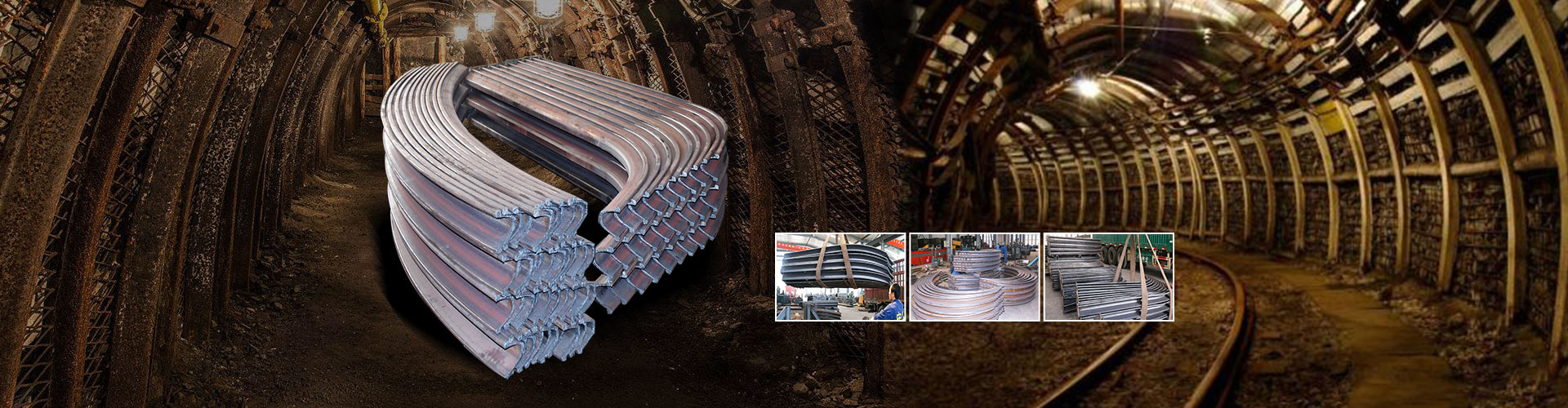

uSteel Support

U Steel Support bracket is a kind of passive support for coal mine support. It has high tensile strength and compressive strength, good toughness, high supporting force, large supporting strength and can be used repeatedly. It is widely used. In the mine u lane, especially in deep complex roadways and soft coal seam roadways.

USteel Support

product description

product description

The U Steel Support produced by different countries have different cross-sectional shapes, geometric parameters and materials. Currently, U Steel Support models produced in China mainly include U18, U25, U29, U36, and so on.

four

advantages of the product

NO.1

NO.1

The U steel support bracket is a kind of passive support for coal mine support, and has high tensile strength and compressive strength.

NO.2

U Steel Support brackets are widely used in mine u lanes, especially in deep complex roadways and soft coal seam roadways.

NO.3

The U steel support bracket has good toughness at the same time, high support force, large support strength and can be used multiple times.

NO.4

It is of great significance to flexibly select the type, structure and shed distance of the U-shaped steel bracket to fully utilize the support performance of the bracket.

USteel Support

Structural analysis

Structural analysis

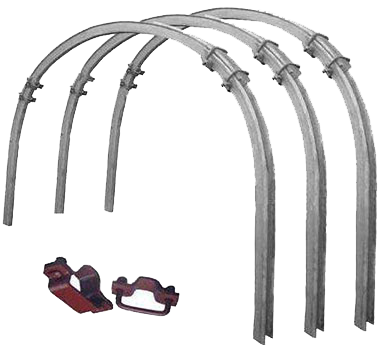

The U Steel Support bracket is mainly composed of a top beam, a column leg, a connecting piece, an inter-frame tie rod and a backing material.

- Top beam

- Column legs

- Connector

- Pull rods

- Backing

The top beam is arc-shaped, and its number is divided into one section and multiple sections depending on the section size of the roadway, the force of the bracket, and the transportation conditions.

There are three types of legs: one is a circular arc at the top and the straight segment at the lower part; the second is all curved and has only one radius of curvature; the third is all curved, but has two curvatures. radius. A base is welded under the column leg, and the size of the base depends on the hardness of the bottom plate;

The connecting piece is a clamping device between the bracket section and the inter-section, which can be used for the connection between the joints, and can also press the two sections of the connected steel joints to provide a pre-tightening force, so that the U-shaped steel has frictional force, thereby ensuring The arched bracket has a certain working resistance and a certain amount of shrinkage.

The role of the inter-rack tie rod is to enhance the overall relative stability of the bracket, and the brackets are coupled from the longitudinal direction to form a whole.

The backing material is a filling material between the U-shaped steel bracket and the surrounding rock, and the purpose is to make the U-shaped steel bracket close to the surrounding rock, improve the stress state of the bracket, improve its bearing capacity and maintain the stability of the surrounding rock.

USteel Support

The main function

The main function

Compared with other rigid supports, U Steel Support brackets have shrinkage, stable and reliable bearing capacity, adapt to the load and deformation of soft surrounding rock, high utilization rate of sections, convenient support of brackets, small maintenance, high recovery rate of brackets, and reduced pits. Wood use, environmental benefits are very obvious.

-

Long support time

Long support time

The U Steel Support bracket is subjected to large pressure and long support time, and is easy to install and is not easily deformed.

-

Large bearing capacity

The U Steel Support bracket has shrinkage, stable and reliable bearing capacity compared with other rigid supports, and adapts to the load and deformation of the soft surrounding rock.

-

Easy to maintain.

Easy to maintain.

The U Steel Support bracket has high cross-section

utilization, convenient support for the support, and small maintenance.

-

High environmental benefits

The U Steel Support bracket has a high recycling rate and reduces the use of pit wood, and the environmental protection benefits are very obvious.

USteel Support

Preparation before construction

Preparation before construction

Due to the production batch, the specific model is different, the above of pictures are for reference only, for further details you can contact our sales staff to carry out the specific verification .

1.The required U Steel Support bracket materials, construction tools, etc. are fully prepared and transported to the construction site.

2.Careful inspection of the roof condition revealed that the dangerous rock was removed with a long handle tool.

3.Before erecting the U Steel Support bracket, the excavation is applied to the front of the beam to control the roof and advance support.

4.Check the quality of the roadway excavation work at the shed, and the under-excavation of the roadway must be processed to meet the design requirements.

5.Find the middle waistline and mark it: Pull a midline through a small line through the section where the U-shaped steel bracket is to be erected, and lead the waistline to both sides to make a mark.

USteel Support

Our quality is trustworthy

Our quality is trustworthy